Open cast

Open cast molding is the simplest and most common molding method for thermoset polyurethanes.

Advantages: Since pressures and temperatures in the molding process are relatively low (ambient pressure and temps below 250F), the molds are more cost effective and can be made from a variety of materials including polyurethane.

Open cast molding is good for parts with relatively open tolerances on one surface. If tolerances are tighter a secondary finishing operation is an option.

Transfer and Liquid Injection

In transfer or liquid injection, pressure is used to force the liquid polyurethane out of a reservoir and into the mold. Materials are generally injected at the bottom of the part and vented at the top for the prevention of air entrapment.

Advantages: Makes use of fairly low cost molds and can achieve thin cross-sections. Parts will have a sprue and an open surface for venting air which will require a finishing operation.

Compression

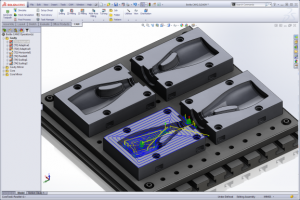

The part is split on a parting line, the halves are filled and the material is allowed to gel. The mold is then closed and placed into a compression press.

Advantages: Compression molding yields a finished part with detail on all sides. Molds can be more expensive than those used in open casting or transfer, but parts can be quite detailed and elaborate.

In rotational molding liquid polyurethane is poured in a reservoir. The spinning device is started and centripetal force moves the material into the mold.

Please Contact us for further details or to answer your questions.