General: In these general terms and conditions of sale (the “Terms”), Plan Tech, Inc. is referred to as “Seller”, the party to whom Seller’s quotation or invoice is addressed, or who is seeking to purchase goods offered on Seller’s website is referred to as “Buyer”, and Seller and Buyer are collectively referred to as the “Parties” and each individually as a “Party”. All sales of Seller to Buyer are subject to these Terms and these Terms are a binding contract between and among Seller and Buyer. Any purchase order, acknowledgement, or other communication from Buyer that contains terms and conditions in addition to or inconsistent with these Terms will not be binding upon Seller, unless acceptance of those terms and conditions is made in writing by an authorized representative of Seller. Quotations; Acceptance of Orders: Written quotations automatically expire 30 days after the date issued unless otherwise specified in the quotation. A verbal quotation expires on the business day in which it was made. All quotations are subject to these Terms and to Seller’s written order acknowledgment. Orders become effective only when accepted by Seller’s written order acknowledgment. For orders placed on Seller’s website, Buyer is making an offer […]

Case Study: Dissipating static electricity in urethane rollers and urethane wheels by using an anti-static additive

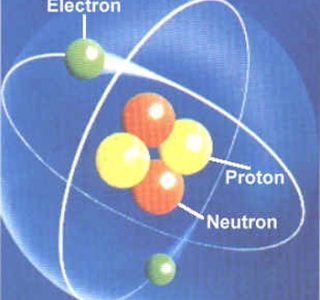

Dissipating static electricity in urethane rollers and urethane wheels by using an anti-static additive. Static electricity is an invisible field of protons, neutrons, and electrons found in anything that has potential to move. Each atom has its own properties, and characteristics. One of these properties is called an electrical charge. Protons have what is called a “positive” (+) charge which is the root of static electricity build up in urethane products. Electrons have what is called a “negative” (-) charge. Neutrons have no charge, they are neutral. When an electrical charge such as static electricity builds up it can have a violent discharge when the protons find the easiest path to the earth’s surface called ground. Rolling friction will cause an imbalance of neutrons if the electrical charge can not get to ground. Urethane by its self is non-conductive and does not dissipate any electrical charge and without the correct formula a dangerous amount of electricity may build up on isolated parts and has also caused problems for industries such as paper factories processing paper with urethane rollers for high-tech equipment. If the urethane were to be produced without an anti-static additive the positively charged wheel and surplus […]

Directory of Engineering Software used for Urethane Mold Design

Want to know which Software is used in designing Polyurethane Molds? You’ve come to the right place! Plan Tech strives to use the latest in design software technology for the designing of complex urethane molds. We utilize SolidWorks to design all of our open face and compression molds per customer specifications. When we have completed our design that has been approved by the customer we machine them using CAMWorks at our in-house machine shop. This creates a faster “concept to production” environment to produce superior parts for our customers. Below is a list of the software used for designing urethane molds: CAD Design Software (Computer-Aided-Design) SolidWorks: SolidWorks is a solid modeler, and utilizes a parametric feature-based approach to create models and assemblies. DS Solidworks Corp has sold over 1.5 million licenses of SolidWorks worldwide. This includes a large proportion of educational licenses. The Sheffield Telegraph comments that Solidworks is the world’s most popular CAD software. Its user base ranges from individuals to large corporations and covers a very wide cross-section of manufacturing market segments. AutoCAD: AutoCAD is a commercial computer-aided design (CAD) and drafting software application. AutoCAD is used across a wide range of industries, by architects, […]

Directory of Polyurethane Additives for Cast Urethane Parts

Want to know which additives are used in Polyurethane? You’ve come to the right place! Plan Tech a leader in cast urethane manufacturing, process’s urethane additives from the world’s leading chemical companies. Whether its enhanced lubricity for high abrasion resistance applications or for anti-static wheels for shoppers who don’t want to be zapped touching a metal cart. Having more than 30 years experience in the polyurethane industry provides Plan Tech the specific knowledge of incorporating polyurethane additives: FDA Urethane Additives: Eriez POLYMAG® a leading manufacturer of Metal Detector systems, allows urethane molders to produce FDA Metal Detectable and X-Ray Visible urethane parts for food contact applications that can satisfy varying levels of detectability. Acceptable for repeated contact with food under section #177.21000, subpart F. Can be used in continuous and repetitive contact with dry, aqueous and fatty foods. Typical features of these polyurethanes include outstanding abrasion resistance, high tensile and tear strength, and excellent load bearing capabilities. High Durometer Urethane Additives: Air Products Founded in 1940 provides world leading food curative that can be used in the manufacture of polyurethane elastomers intended to contact dry food. Air Products has built a reputation for its innovative culture, operational excellence. […]

Custom Molded Polyurethane Gears – Made In USA

Custom molded polyurethane gears are typically molded to a size that we can offer a low-cost replacement polyurethane gear with any tooth number or pitch for high demand applications. A keyway may be added into the custom molded polyurethane gears being driven or an idler bearing may be incorporated into the design. From prototype pieces to high volume our team of engineers will design the custom molded polyurethane gears for your demanding application requirements. We also have several different polyurethane additives to alter how the urethane handles certain environments. Our most common additive is called Armorglide which will add lubricity to the polyurethane elastomer and add additional abrasion resistance to any custom molded polyurethane gears sizes or configurations. Polyurethane gears offer what other materials can’t, polyurethane is chemical resistant and will absorb an impact and return to its original size even after years of abuse. Not all custom molded polyurethane gears are made completely from polyurethane, in high-stress applications, a steel core will be added to increase the load capacity. Common applications requiring a steel core are custom molded polyurethane gears that will drive a track in high weight machinery. We also stock special material for FDA custom molded polyurethane […]

Polyurethane Pinion Gears – Pinion Urethane Gears

Polyurethane pinion gears are supplied in two different styles. The most common rack and pinion polyurethane gears setup allow the gear to travel horizontally or vertically while ring and pinion designs will increase torque and allow 90-degree output shafts in a compact design. Polyurethane pinion gears have a long service life compared to other types of gears for many reasons including noise abatement, chemical and corrosion resistance. Most common applications of polyurethane pinion gear are used in manufacturing, assembly lines, conveyor belt and printing systems. At Plan Tech we have an in-house machine shop capable of making molds for polyurethane pinion gears as well as metal cores or hubs for high strength designs. The lower tooling costs of polyurethane compared to injected plastic parts with an increased strength due to polyurethanes ability to absorb an impact and return to its original size even after years of abuse. Polyurethane pinion gears also offer unique noise reduction properties vs similar materials in quieter operating machines with increased run time. Plan Tech can hold tight tolerances for encoded polyurethane pinion gears and can reverse engineering existing polyurethane pinion gears as well as prototype parts for new custom applications. Plan Tech also […]

Urethane Helical Gears – Poly Helical Gears

Urethane helical gears are custom cast from high-quality material to produce a gear that is chemical resistant. Urethane helical gears are manufactured at Plan Tech with speed and precision, they are available in any size or pitch needed for the specific application. In areas with limited space custom helical urethane gears, applications include rack and pinion setups to allow 90-degree output shafts in a small configuration. Urethane helical gears are also available with tight tolerance requirements to process liquids in a pitch style set up. At Plan Tech we can reverse engineering existing urethane helical gears as well as produce new styles and sizes for custom applications and can incorporate custom key ways if required. In high strength applications, a steel core may be added to increase the load of the urethane helical gears. Common urethane helical gears have the teeth at an angle (19º 31′ 42″) for increased load capacity and quiet operation due to urethanes great ability to have greater physical properties in medium hardness vs traditional steel helical gears. The helical urethane gear style provides several key benefits over the straight gears. Being meshed at an angle allows the gear to operate quieter than the straight cut gears, especially at high speeds Also […]

Dual Durometer Urethane Parts – Dual Duro Molded Urethane!

Dual Durometer Urethane Parts ? You’ve come to the right source! Dual Durometer Urethane Parts are a great choice for material because it is capable of handling extreme loads; urethane will also help absorb vibration and shock. Plan Tech has been manufacturing new custom dual durometer parts for over 30 years! Some common dual durometer urethane components that we manufacture have a 75D durometer hard inside diameter that is chemically bonded to a softer outside surface. We utilize the best in class polyurethane from world’s leading polyurethane manufacturers and manufacture the industries largest selection of high-quality Dual Durometer Molded Parts some of which include: Dual Durometer Parts Dual Durometer Urethane Rollers: Dual durometer urethane rollers have an endless combination of sizes that can be manufactured. Multi hardness and dual durometer urethane rollers offer unique solutions which can be manufactured for a wide range of industrial applications. Dual Durometer Urethane Wheels: Dual durometer urethane wheels are typically cast with a 75D durometer core or rim which is our hardest, toughest material available. Being able to cast dual duro wheel cores allow our customers to deviate away from the traditional cast aluminum or steel cores significantly reducing cost and lead time. Dual Durometer Urethane […]

Poly Covered Bearings – Polyurethane Covered Bearings

Poly covered bearings are one of Plan Tech’s specialty industrial urethane bearings that we manufacture. Poly covered bearings are available in any thickness up to 12” diameter and can be of any hardness. Custom profiles may be added to the outside dimension for match any rolling surface. Poly covered bearings operate quiet and smooth vs similar materials at a fraction of the cost of OEM replacements. Armorglide additives can be added to increase abrasion resistance while adding lubricity are available for high use applications. Poly Covered Bearings At Plan Tech we can tailor the urethane polymer to change how equipment performs for one-off applications. We can also reverse engineer existing poly covered bearings to match OEM parts. Our poly covered bearings use the best material urethanes available and do well in high-speed applications. The urethane coated bearings that we manufacture won’t mar or mark the rolling surface. We can cover both double shielded bearings and sealed bearings. For custom bearings sometimes we will make special molds to be able to process unique applications. Common applications are found in shipping centers, assembly lines, and roller track shelving units. […]

Hubbed Urethane Rollers – Hubbed Rollers

Hubbed urethane rollers are manufactured for a precision fit in high abuse applications. Hubbed urethane rollers are typically coated on a steel or stainless core that can be produced and manufactured in house. The urethane diameter is ground to a tolerance of +/-.003 for maximum concentricity and service life. Hubbed urethane rollers may also have any key way needed or set screw location. Custom profiles in the urethane rolling surface are also machined to match any rolling profile needed for the applications. Urethane has a great ability to absorb and impact and return to its original size even after years of abuse. Hubbed urethane rollers have a recommended working temperature for maximum service life of -10 to 170F making urethane an ideal choice for most applications. FDA requirements are also no problem for Plan Tech. We any supplied any hardness hubbed urethane rollers and any size up to 12” diameter. Anti-static additives are available for urethane rollers that are rolling against a constant surface. Anti-static urethane will bring the electrical charge to the outside of the hubbed urethane rollers where it will be grounded. This will help light materials from sticking to the urethane rollers for smooth operation. In […]

Armorglide Filled Urethane – Armorglide Urethane Parts!

Armorglide filled urethane capture the benefits of UHMW without the expensive process. Depending on the application high or low friction formulations may be achieved when using armorglide between 5% and 10% mixture. At Plan Tech we will high speed mix the armorglide into the urethane with state of the art urethane mixing machines to achieve a superior mixture between the armorglide particles and the urethane resin. The benefits of using with these surface-activated particles will increase abrasion resistance while reducing the coefficient of friction. Many cast urethane parts, and other wear surfaces are now being made using armorglide filled urethane to reproduce high wear parts at a fraction of the cost of similar materials. Armorglide filled urethane increases abrasion and tear resistance and a reduced coefficient of friction when compared to traditional urethanes. In high wear applications, a hard hardness of 95A to 75D is recommended for long life service when using filled urethane. Normal operation temperature for optimum life span is between -10 and 170F. From prototype pieces to high volume Plan Tech can help with design changes and unique challenges. Often times OEM UHMW parts will be discontinued or a special profile will be needed in custom equipment. Armorglide […]

Urethane Idler Wheel Rollers – Polyurethane Idler Rollers

Urethane idler wheel rollers are designed to operate in any condition. Common urethane idler wheel rollers styles include convex, smooth or concaved profiles to match the applications rolling surface. Urethane idler wheel rollers will absorb an impact and return to its original size while retaining a smooth and quiet operation. Urethane is also resistant to many chemicals and does very well in outdoor applications with additives to enhance color stability. Other additives may be added to increase abrasion resistance while adding lubricity to any hardness for urethane idler wheels. Most urethane rollers will consist of an aluminum or steel core with a bearing or drive keyway. In high abuse applications, a medium hardness of 95A is recommended for long life service vs similar materials. In feeding applications, soft durometers are available with anti-static additives to dissipate any electrical build up from processing material. Normal operation temperature for optimum life span is between -10 and 170F. From prototype pieces to high volume Plan Tech can help with design changes and unique challenges. Often times OEM urethane idler wheel rollers will be discontinued or a special profile will be needed in custom equipment. Plan Tech will learn the application and recommend […]

Metal Backed Urethane Sheets – Metal Backed Polyurethane

Metal backed urethane sheets are commonly found in replacement parts for assembly lines. Made from high-quality material specified to your requirements, metal backed urethane sheets can be cast up to 4′ foot square pieces. When used in assembly line applications the metal backed urethane sheets will be fastened in ways to act like a bumper or guide to keep product flowing in the right direction. Urethane has excellent abrasion resistance vs similar materials with additives available for use with existing X-ray equipment or FDA requirements. Plan Tech can also water jet cut urethane parts in any profile needed for the application into the metal backed urethane sheets. Often times supplied in a soft durometer with additives that increases lubricity and abrasion resistance. Urethane also has a great ability to absorb an impact and return to its original shape in most temperature conditions. Plan Tech’s metal backed urethane sheets also have 30 years of bonding urethane to substrates experience which yield a bond tear strength greater than the urethane for ideal service life conditions. Our engineering department can turn your idea, sketch, drawing or CAD file into custom urethane parts. We will reverse engineer to recreate any urethane part for production or one-off […]

Cast Urethane Pulleys – Urethane Pulleys

Urethane Pulleys ? You’ve come to the right source! Urethane pulleys are common in manufacturing and shipping centers that process items through an assembly line. Urethane pulleys are manufactured at Plan Tech from start to finish – we can add any needed keyway or profile to the urethane pulley. Cast urethane pulleys have excellent physical properties and service life vs. similar materials and will operate in any condition with a smooth operation. Cast urethane has a great ability to absorb an impact and return to its original shape that will reduce vibrations and equipment downtime. We offer many types of high-quality cast urethane pulleys: Tight Tolerance Cast Urethane Pulleys Polyurethane Pulleys with Steel Cores: Polyurethane pulley steel core are custom cast to produce pulleys for any industry requiring a high-performance material with a long service life. Since polyurethane is FDA compliant – polyurethane pulleys with a steel core can be easily reproduced for low-cost replacements and can be cleaned using most chemicals. Urethane Sheaves and Pulleys: Urethane sheaves and pulleys are frequently used to protect steel cables for lifting applications. Urethane has a great ability to absorb vibration for a smooth and quiet operation. Urethane sheaves pulleys are commonly […]

Convex Urethane Rollers – Convex Poly Rollers

Convex urethane rollers are used in a wide variety of industrial applications. Convex urethane rollers typically will taper on each half of the roller with a steel or stainless core for bearing applications or a bronze bushing may be installed. Common places you see convex urethane rollers are on boat trailers and industrial packaging equipment. The convex part of the roll will be machined and any profile needed for the loading application and may be achieved at our in-house machine shop. Any durometer or color is no problem for Plan Tech. Convex urethane rollers are an ideal choice for high demand applications or in extreme weather. Urethane will also absorb an impact and return to its original size even after years of repeated abuse. Convex urethane rollers are found in all different lengths and outside dimensions which we have the expertise to manufacture. Tight tolerances or FDA urethane additives for food grade requirements are also available. We also can strip and recoat worn out rollers. Most customers have noted significant improvement in operations once the convex rollers were treated with urethane. If we find that your convex urethane rollers are completely worn out, no longer true or warped we can […]

Polyurethane Sheet Stock – Polyurethane Sheeting

Polyurethane sheet stock is available in any hardness or color. At Plan Tech we can cast polyurethane sheets up to 4′ by 4′. Tight tolerance polyurethane sheet stock is also one of our manufacturing specialties. Polyurethane sheet stock is cast from high-quality material and is custom made to any specification required for the application. Urethane has a great ability to absorb an impact and require to its original shape even after years of abuse in almost any environment. Common profiles of OEM urethane parts can be reproduced from polyurethane sheet stock and is a great choice for manufacturers with water jet machine cutting capabilities. Polyurethane sheet stock is also available with a variety of additives that will tailor physical properties of the urethane for the applications. Our most popular additive will add abrasion resistance and lubricity to the urethane parts providing an extended service life vs similar materials. Our engineering department can turn your idea, sketch, drawing or CAD file into custom urethane parts. We will reverse engineer to recreate any urethane part for production or one-off urethane pieces. The engineering department uses SolidWorks and our machine shop uses CamWorks for 3 axis milling. Our equipment includes CNC […]

Cast Polyurethane Gears – Polyurethane Gears

Cast polyurethane gears for extreme environments are one of the critical components that we specialize in. Cast polyurethane gears are available with a steel core for high strength applications or a custom key way. Custom cast polyurethane gears will often times outperform OEM replacements. Additives may also be added to improve lubricity and aid with abrasion resistance. Any color or hardness may be changed to tailor how a machine will perform for special applications. Cast polyurethane gears will absorb an impact or chain mismatch for a smooth and quiet operation vs similar materials. Prototype cast gears from a discontinued gear or print may be machined to a print at Plan Tech’s state of the art in-house machine shop. High volume gears are often times compression style molded to print with little or no secondary operations. This style of molding cast polyurethane gears allows us to produce a high-quality urethane gear for often times less than OEM replacements. Custom cast urethane gears up to two feet in diameter can be molded into any hardness or profile. For over 30 years we have focused on using speed and precision to rapidly deliver the highest quality industrial cast urethane products and FDA approved […]

Urethane Roller Bearings – Polyurethane Roller Bearings

Urethane roller bearings are a number one choice material in all high usage conveyor systems and shipping centers. Coated on a high-quality bearing of your choice, Plan Tech for the last 30 years has specialized in molding any profile needed for the application. From prototype and high volume Plan Tech will deliver high-quality precision cast urethane roller bearings. Most common applications require a 95A hardness that will operate smooth in any climate. We also stock many additives such as Armorglide to add lubricity and abrasion resistance to any profile urethane roller bearings. With state of the art equipment, Plan Tech can accommodate large or small roller bearings in any volume needed. Offered in single-bearing and double-bearing styles, and inch and metric size. Radiused edge, grooves, and tight tolerances are also available. These profiles allow you to use a standard part in your unique application. At Plan Tech we can also reverse engineer existing urethane roller bearings to match OEM originals often times for less. Some customers have changed the hardness of the urethane for a special application. Urethane roller bearings will also help absorb an impact while reducing the vibration of the load and machine to help protect equipment. For […]

Urethane Spur Gears – Polyurethane Spur Gears

Urethane spur gears have been used in many applications from toy cars to large equipment. The urethane spur gears are typically cast using compression style molding. Plan Tech’s precision made cast urethane spur gears are available in any profile, hardness or color for any requirements and functionality. Spur gears will also adapt for any mismatch and will operate with a reduced level of noise vs similar materials. Spur gears also perform very well in high RMP applications with a long service life even when used outdoors with an operation temperature of -20 to 170F. Polyurethane spur gears are not affected by most chemicals and are non-conductive. Reverse engineering existing spur gears from worn out or discontinued parts is no problem for Plan Tech. For high strength designs, most spur gears will have a steel core often times with a keyway which we are able to produce the complete spur gear in-house with excellent lead times. We can also reclaim worn our urethane spur gears if a core is present for often times less than the cost of OEM replacements. Our inspection dept will make sure every detail and requirement are met or exceeded for each order to ensure the […]

Dual Durometer Urethane Wheels – Made In USA

Dual durometer urethane wheels are typically cast with a 75D durometer core or rim which is our hardest, toughest material available. Being able to cast urethane wheel cores allows our customers to deviate away from the traditional cast aluminum or steel cores greatly reducing cost and lead time. Unlike cast aluminum or steel we can cast the core to size with little or no secondary machining work. After we cast the core to the dual durometer urethane wheel it will be treated and processed with a coat of chemical bonding agent. The finished product will have a bond strength as great as the tear right of the material that will be coated on the core. Dual durometer urethane wheels hold up very well against high-impact uses and will absorb a lot of the vibration from the impact but are not recommended for high load applications. Typically coated in a soft hardness for the application the urethane will have a long service life with a smooth and quite operation vs similar materials. At Plan Tech we can cast any durometer outside coating which is ideal for some customers trying to alter the way a machine is performing. We also have a […]