Polyurethane bearing pads are manufactured by Plan Tech in our fully equipped in-house cast polyurethane facility and machine shop. We utilize only the best quality polyurethane materials from globally recognized chemical producers to ensure the properties of our polyurethane bearing pads are premium standard. With the expertise of our team of engineers who rank among the best industry and urethane facility that is the largest in the industry, we can manufacture polyurethane bearing pads that meet the requirements of any application.

We have been in the business of producing polyurethane bearing pads among other cast polyurethane parts over the past 30 years. Being one of the largest industrial cast polyurethane manufacturers of the products in the sector with all our urethane bearing pads meeting international standards. To ensure high volume production and maintain consistency in quality, we always apply speed and precision. We cast the polyurethane into a mold to make the part using our in-house machine shop using our state of the art urethane facility. Our engineers have the technical know-how to combine different multiple hardness in a single bearing which allows us to custom make bearing pads that will meet the demand of your application.

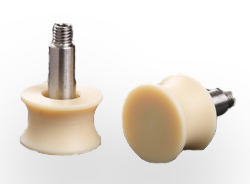

Therefore, our polyurethane bearing pads are available in different durometers as well as colors. Our polyurethane bearing pads can be relied on for their high-performance ability and long service life. That is, they boast impressive ability to resist abrasion, corrosion, and chemical and can withstand environments with harsh conditions. We create complex molds for our in-house use as well as many of the components that are molded into customer products. Molds are machined from aluminum or tool steel depending upon tool life requirements. The inserts and cores that we manufacture are made from a wide variety of metals and plastics including UHMW PE, ABS, aluminum and steel. The machining of custom polyurethane parts and components requires special skills and dedicated equipment. In many instances, we have developed custom equipment for cutting, trimming, staking and deburring per our customers’ requirements.

Please Contact us for further details regarding machining cast polyurethane bearing pads!