Polyurethane square bar stock is rapidly produced at Plan Tech on our custom polyurethane manufacturing casting tables designed to produce any thickness or size bar. Our table has a movable fence to accommodate any width or length required for the polyurethane square bar stock. Metric or oddball sizes are no problems for us!

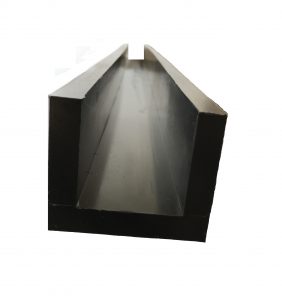

Custom cast from high-performance material our polyurethane square bar stocks will outperform rubber bars 3:1 with a much tighter tolerance. Unlike OEM polyurethane square bar stock Plan Tech can modify any profile or design into the bar for bolt-on applications or unique challenges. Tight tolerance polyurethane square bars are molded in tooling designed by at Plan Tech.

Polyurethane square bar stock can be rapidly produced for a number of different applications from die cutting to bumpers for large industrial equipment. Often times we find that shipping companies utilize our polyurethane square bar stock to protect delicate electrical equipment in transit. Whatever the application may be Plan Tech may make a recommendation on how to tailor our urethane for maximum performance and service life. A variety of additives may be added to enhance physical properties per the polyurethane square bar stock application. FDA formulas are also available at Plan Tech in any hardness for the application.

Open cast molding is the simplest and most common molding method for thermoset polyurethanes. Advantages: Since pressures and temperatures in the molding process are relatively low (ambient pressure and temps below 250F), the molds are more cost effective and can be made from a variety of materials including polyurethane. Open cast molding urethane parts is good for parts with relatively open tolerances on one surface. If tolerances are tighter, a secondary finishing operation is an option.

In transfer or liquid injection, pressure is used to force the liquid polyurethane out of a reservoir and into the mold. Materials are generally injected at the bottom of the part and vented at the top for the prevention of air entrapment. Advantages: Makes use of fairly low-cost molds and can achieve thin cross-sections. Parts will have a sprue and an open surface for venting air which will require a finishing operation.

Please Contact us for further details regarding polyurethane square bar stock!