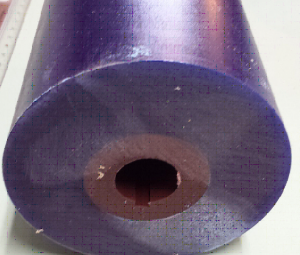

Urethane cone liners have a remarkable high-performance ability, and the ones manufactured by us are custom made to solve all tear and wear issues that are related to the bulk transportation of several types of materials. Renowned for its exceptional capability to resist abrasion and other tough conditions. Our urethane cone liners are, therefore, the perfect solution for offering protection to cones against abrasive compounds.

Urethane Cone Liners are also ideal for sticky materials and are designed to provide producers with much the needed long-lasting protection which helps in resisting abrasion, impact and concrete build-up. It may also interest you to know that our urethane cone liners make installation easy to carry out while also ensuring a reduction in the cost of maintenance as well as downtime. Finally, the urethane cone liners we offer are capable of offering a considerable reduction in noise; they are known to weigh lighter than other cone liners and provide a service life that is significantly longer than that provided by rubber and steel liners or any other type of liners for that matter. So, regardless of the requirements of your application, you can be assured of finding the perfect urethane cone liner among the variety we have on offer.

Two common urethane Molding Techniques:

Molding Urethane Parts Open cast

Open cast molding is the simplest and most common molding method for thermoset polyurethanes.

Advantages: Since pressures and temperatures in the molding process are relatively low (ambient pressure and temps below 250F), the molds are more cost effective and can be made from a variety of materials including polyurethane. Open cast molding urethane parts is good for parts with relatively open tolerances on one surface. If tolerances are tighter, a secondary finishing operation is an option.

Molding Urethane Parts Compression

The part is split on a parting line, the halves are filled and the material is allowed to gel. The mold is then closed and placed into a compression press.

Advantages: Compression molding yields a finished part with detail on all sides. Molds can be more expensive than those used in open casting or transfer, but parts can be quite detailed and elaborate.

Please Contact us for further details regarding Urethane Cone Liners!