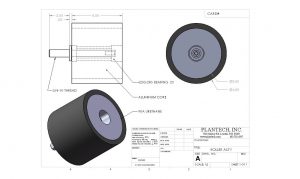

Urethane Idler Rollers are tops in abrasion and wear resistance. Common urethane idler rollers size range from diameters ½” to 6″ and face widths from ½” to 48″. Plan Tech has a full line of post-secondary operations, we can finish and assemble your urethane idler rollers to meet your most stringent specifications. All colors and durometers are available with our custom manufactured urethane idler rollers.

Custom Urethane Idler Rollers

A variety of additives can be added to enhance wear properties, add lubricity, UV stabilized, flame retardant, or to reduce static build up. We also carry a metal detectable additive which can also be added for FDA urethane idler rollers. Castings, stampings, weldments or fabricated cores are no problem for us! Our urethane idler rollers can be specifically tailored for light, medium and heavy-duty applications. We can customize the urethane rollers to meet even the most demanding applications.

We have several different mold making options when manufacturing molds for urethane idler rollers including the following types:

Urethane Idler Rollers Moldmaking Options

Open cast molding

Open cast molding is the simplest and most common molding method for thermoset polyurethanes.

Advantages: Since pressures and temperatures in the molding process are relatively low (ambient pressure and temps below 250F), the molds are more cost effective and can be made from a variety of materials including polyurethane. Open cast molding is good for parts with relatively open tolerances on one surface. If tolerances are tighter, a secondary finishing operation is an option.

Transfer and Liquid Injection

In transfer or liquid injection, pressure is used to force the liquid polyurethane out of a reservoir and into the mold. Materials are generally injected at the bottom of the part and vented at the top for the prevention of air entrapment.

Advantages: Makes use of fairly low-cost molds and can achieve thin cross-sections. Parts will have a sprue and an open surface for venting air which will require a finishing operation.

Compression

The part is split on a parting line, the halves are filled and the material is allowed to gel. The mold is then closed and placed into a compression press.

Advantages: Compression molding yields a finished part with detail on all sides. Molds can be more expensive than those used in open casting or transfer, but parts can be quite detailed and elaborate.

Rotational

In rotational molding, liquid polyurethane is poured into a reservoir. The spinning device is started and centripetal force moves the material into the mold. Advantages: All manner of molds can be used in this process and it can be very cost effective when molding complex shapes and thin cross-sections.

Tight Tolerance Urethane Idler Rollers

We can add value to your products with our strong engineering support, urethane polymer experience and constant focus on meeting all delivery requirements. Our rapid prototyping capabilities have also received particularly positive feedback – we frequently go from “Print to Part” in 10-15 business days! Everything we manufacture is MADE IN THE USA!

Please Contact us for further details regarding your urethane idler rollers application!