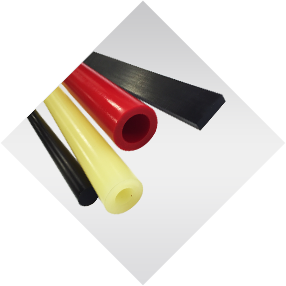

Urethane round rod stock is often used as a replacement for plastic or nylon components and provides an obvious upgrade over the conventional material. Plan Tech’s urethane round rod stock has a much-improved resistance to wear/abrasion and can outlast nylon by as much as four times.

Our team of engineers who rank among the best in the industry, boast years of experience in producing top-notch urethane round rod stock. No doubt polyurethane is a world class raw material; still, our engineers leave no stone unturned in ensuring the polyurethane round rod stock manufactured at Plan Tech are second to none in quality.

We boast an in-house machine shop that is fully-equipped with sophisticated machinery which allows our team of experts to produce polyurethane round rods that are renowned in the industry for their high level of efficiency, durability, and tolerance. To ensure we consistently provide world-class rubber round rod stock, we only utilize first grade materials.

Our rubber round rod stock has excellent resistance to abrasion, corrosion, oils, chemicals, solvents, and oxidation while maintaining high tensile strength and resilience. Also, our team of engineers consistently apply speed and precision during its production process. Therefore, like all our highly valued customers, you can count on the Plan Tech team to meet your high volume demands in record timing and with maximum accuracy. Whether you are a start-up company or global leader, we can add value to your products with our strong engineering support, urethane polymer experience and constant focus on meeting all delivery requirements. Our rapid prototyping capabilities have also received particularly positive feedback – we frequently go from “Print to Part” in 10-15 business days! Everything we manufacture is MADE IN THE USA and our production capabilities include:

- In-house custom mold manufacture

- Waterjet cut urethane parts

- Automated adhesive application for high strength urethane bonding to metal and non-metallic substrates

- Open cast, rotational, compression and liquid injection molding

- High speed automated and manual finishing equipment

- Post-secondary assembly

- World class metal preparation

- On-site testing

- Full in-house machine shop with multiple CNC mills, lathes, grinders, welding and sheet metal fabrication

Are you interested in cast Urethane Round Rod Stock? Please Contact us so we can help solve your requirements and work with you on your specific application!