Cast urethane parts aren’t just useful for the largest fortune 500 industrial companies in the world – they’re also incredibly useful and widely used by the typical small businesses and startups alike. If you are considering investing in urethane parts for your business, there a couple of key reasons why cast urethane parts can really benefit your business and contribute to making your production as efficient as possible. If you’re specifying a new industrial wear part and are deciding between materials, here are some reasons why you should specify cast urethane parts: 1. Urethane parts can be shaped accurately No matter what shape you want your cast urethane parts to be, we can design them for your application by using extreme precision. We can create any custom cast urethane part that’s up to 30 inches long with a tight tolerance of error in the process. You’ll get a cast urethane part that is exactly as your project requires. 2. Several different finishing options to choose from One important factor about cast urethane parts is that the composition of the parts can easily be manipulated. You can choose whether you want an end product that is rigid, flexible […]

Case Study: How to Process Urethane Parts by Incorporating FDA Approved Urethane Additives

Urethane is one of the most versatile and widely used materials in manufacturing. It is incredibly durable and outstands wear and tear and is also relatively inexpensive. Fortunately, many improvements have been made to make urethane’s performance that much better. Now, we are able to produce FDA approved urethane for a variety of products. This has several advantages, namely being able to use FDA approved urethane for food preparations. What Can I Use FDA Approved Urethane For? FDA approved urethane is used for a variety of tasks and purposes in manufacturing facilities around the world. While it is mainly used for food preparation services, it can also be used for many other things including gaskets, seals FDA approved parts (including FDA approved sheets, FDA approved pads, FDA approved washers and more). If you are in the food industry and need a material that is abrasion resistant and is also approved by the state to be used to handle food, use FDA approved urethane for something customized and long-lasting. Our clients specify our FDA approved urethane for several different applications such as: Food Preparation Food Liners Food Paddles Mixing Paddles Sorting Tables Food Dividers Mixers […]

Grinding Urethane Rollers – Grinding Polyurethane Rollers

Grinding urethane rollers is just one of Plan Tech’s specialized services that we offer. Custom cast urethane rollers are precision cast before being sent to Plan Tech’s in house machine shop. For the last 30 years, we have been building and updating our grinding capabilities to accommodate just about any size or hardness urethane roller. Frequently we are sent worn out rollers and wheels from our customers with metal cores or “rims” that are still in useable shape. We are able to save our customers thousands of dollars by being able to reprocess worn out rollers with new urethane coatings and grinding urethane rollers. No matter what material the roller was previously coated in, Plan Tech will be able to strip and re-produce OEM or aftermarket urethane rollers to just about any size or to match the profile of the material the roller will be processing. Plan Tech uses the best prepolymer from world leading chemical and polyurethane manufacturers to produce urethane rollers that are chemically resistant to most solvents with extremely tight tolerances. Grinding urethane rollers is not an easy task, Plan Tech has build custom one off machines capable of performing such precision. We use special grinding wheels […]

Grinding Urethane Parts – Grinding Custom Urethane Parts

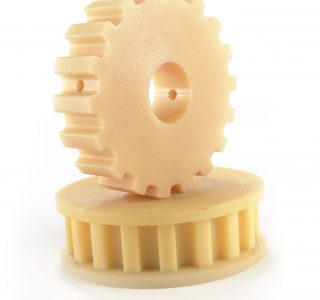

Grinding Urethane Parts ? You’ve come to the right source! Grinding urethane parts requires specialized machines and skilled knowledge as each hardness will machine differently. Plan Tech has the ability to grind any hardness urethane parts from chewing gum soft 20A to medium hardness 90A. Harder durometers can also be successfully turned with traditional tool bits. We offer many types of high-quality grinding urethane parts: Grinding Urethane Parts Grinding Urethane Rollers: Grinding urethane rollers is just one of Plan Tech’s specialized services that we offer. Custom cast urethane rollers are precision cast before being sent to Plan Tech’s in house machine shop. For the last 30 years, we have been building and updating our grinding capabilities to accommodate just about any size or hardness urethane roller. Grinding Urethane Wheels: Grinding urethane wheels is a common practice for Plan Tech’s state of the art machine shop. Over the last 30 years, we have made custom lathes and machines to specialize in machine grinding urethane wheels. Skilled machinists are necessary to perform these tasks as it is completely different than machining metal. Urethane Grinding Specialists: Urethane grinding is extremely specialized and most machine shops do not grind any type of material. […]

Urethane Chemical and Solvent resistance chart

Urethane material performs very well against most chemicals and solvents. Plan Tech uses high-quality material from world leading chemical companies. Below is a chart that Ph.D. chemical engineers have developed to help take away some of the stress when designing new urethane molded parts that will be exposed to chemicals. A good rule of thumb is urethane will hold up to most chemicals and solvents as long as the PH level in the exposed chemical is not extremely acidic or basic. Urethane parts will be most resistance to chemicals and solvents exposed to neutral PH levels. Plan Tech recommends the testing of any chemical that is not listed. Sample key rings and or test slugs are available for testing.

How to convert the different Durometer Shore Types

There are many different scales to determine exactly what hardness material your testing. Many of the type scales overlap over different scales and for the most part in the urethane industry “A” scale is used to measure soft durometers and “D” scale for the harder material. Plan Tech uses only the best testing equipment from Rex Gauge Co to ensure our urethane products meet the required hardness. Dual Durometer parts are available from Plan Tech where two different hardness material will be bonded together to form one part. This is extremely popular with rollers requiring a hard core to be used as a rolling bushing while the outside covering needs to be of a softer material to protect the product goods. The industry standard for durometer tolerance is +/-5 points on any of the hardness type scales. For the last 30 years, Plan Tech has provided high-quality urethane parts around the world to many include many Fortune 500 companies, most of whom have been customers for 20+ years.

Urethane Drift Trike Wheels

Urethane Drift Trike Wheels are unlike all traditional wheels. What makes drift trikes drift is the slippery 10’’ x 6’’ rear tires commonly made from PVC pipe. Plan Tech being a world supplier of urethane parts was first approved to make superior urethane drift trike wheels because of the enormous benefits urethane offers. Made from rock hard friction reduced modified urethane our drift trike urethane wheels are commonly referenced to slicker than ice. These are not typical PVC covered wheels but specially cast from solid urethane in any custom size available. We also have competition race wheels available in a softer hardness to still drift the corners but have just a little bit more bite to the road. Available in any color or hardness drift trike urethane wheels are often times bonded directly to an old rim. Send Plan Tech your old drift trike wheels and we will media blast the wheel before coating the wheel with solid urethane. PVC or plastic slip on covers are often times extremely dangerous in bumpy conditions. It is very common for PVC to explode when riding hard and more prone to failure when cold. Urethane solves all theses problems and […]

Urethane Spacers – Custom Polyurethane Spacers

Urethane spacers are commonly found in hardware stores in nominal sizes, Plan Tech specializes in high volume urethane spacers of any size for any high abuse applications. Custom sizes and shapes are no problem for Plan Tech’s in-house mold making fabrication and machine shop. Urethane spacers are used in a variety of different applications, most to isolate vibrations from the connecting parts. Cast from hard or soft urethane or anything in between Plan Tech will engineer the urethane spacers with you on every detail. Custom one-off urethanes spacers are our specialize or we can reverse engineer an existing part. By working directly with the customer allows us to produce parts often times for a lot less than OEM replacements. Plan Tech also selects the highest-quality urethane material from world leading chemical companies to ensure the quality of our parts meets or exceeds the OEM parts. Plan Tech also offers a variety of additives for unique applications where abrasion might be a factor. We stock an additive called armorglide that will increase the lubricity of the urethane spacers just like UHMW with the increased physical properties of urethane. FDA requirements are also no problem for Plan Tech. Simple combination of […]

Industrial Urethane Gaskets – Polyurethane Industrial Gaskets

Industrial urethane gaskets are custom made at Plan Tech for any profile or application needed. Plan Tech will frequently decide to utilize our in-house water jet cutting capabilities and cut any profile from a urethane sheet to produce industrial urethane gaskets configurations. The hardness of gaskets depends on the load it will be sealing, often times industrial urethane gaskets are of medium hardness but can be cast from any hardness urethane material from chewing gum soft to rock hard are available at Plan Tech. Also just about any thickness gasket can be produced. From high volume to one-off custom parts for equipment Plan Tech will work with you on every detail of the gaskets to ensure fitment and long service life ahead. Tight tolerance urethane gaskets have a great ability to seal on an uneven surface and is resistant to many chemicals. High volume industrial urethane gaskets are often times compression molded at Plan Tech for rapid shipments of molded gaskets. Being able to cast complete eliminate the lead time and added cost from running the water jet and is ideal for high volume orders requiring a tight tolerance and if the profile allows for compression molding. From […]

Metal Backed Urethane – Metal Backed Urethane Parts!

Metal Backed Urethane ? You’ve come to the right source! Metal backed urethane parts are extremely common for industrial applications and for the last 30+ years Plan Tech has mastered many different techniques to mold or cut the finished product. A particular strength is the breadth of our in-house capabilities such as grinding urethane parts which, when combined with our extensive experience, enables us to deliver tight tolerance metal backed urethane sheets while maintaining the quality control and cost effectiveness our customers require. The tests are performed according to an established set of standards provided by an accredited testing organization such as the Society for Testing and Materials (ASTM) who define the procedures in detail. At Plan Tech we offer the industries largest selection of high-quality Metal Backed Parts some of which include: Metal Backed Urethane Parts Metal Backed Urethane Sheets: Metal backed urethane sheets are commonly found in replacement parts for assembly lines. Made from high-quality material specified to your requirements, metal backed urethane sheets can be cast up to 4′ foot square pieces. When used in assembly line applications the metal backed urethane sheets will be fastened in ways to act like a bumper or guide to keep product flowing in […]

How to Manufacture Abrasion Resistant Custom Urethane Parts

When it comes to creating custom polyurethane parts, there’s no material – be it an elastomer, plastic or metal – that stands up to abrasion like urethane does. In fact, in some reports, urethane is shown to be ten times more resistant than these materials. If you’re looking for custom urethane parts, there is no better option than using polyurethane. What Types of Abrasion Does Urethane Prevent? While abrasion is often just seen as abrasion, there are specific movements that cause those fractures, nicks and bumps. Was it due to a fluke bump in the process? Something sliding on the custom part? Or something of high velocity that hit the part’s surface? While urethane is well suited to prevent against nearly all types of abrasion, it is best suited for the following: Sliding Abrasion Impingement Abrasion These specific types of abrasions can really diminish the effects of your custom parts. Fortunately going with custom urethane parts is a viable, cost effective option that is incredibly resistant to abrasion. What is Sliding Abrasion and How Do Custom Urethane Parts Prevent Abrasion? Sliding abrasion is when tiny tears occur due to a localized area of high strain when one item […]

Custom Urethane Suspension Bushings – Polyurethane Bushings

Custom urethane suspension bushings are not only found in most of the cars we drive today but in most heavy equipment as well due to the ability for urethane to outlast rubber 3:1. Urethane has a great ability to absorb and impact and return to its original size even after years of abuse. This is an ideal situation for custom urethane suspension bushings no matter what the application is. Plan Tech specialties in reproducing discounted bushings as well as high volume custom urethane suspension bushings. The ability to reproduce prototype pieces as well as high volume allows us to be able to work with small repair shops as well as equipment manufacturers. Custom urethane suspension bushings are available in any color as well as hardness. While most are supplied in a 90A material special applications are no problem. Custom urethane suspension bushings are also found in conveyor systems and bottling facilities. Plan Tech also offers custom suspension bushings to meet FDA requirements with additives like “PolyMag” stainless powder. If the part were to fail the PolyMag additive will be detected during X-ray inspection of the products. Just about any size or shape can be molded at Plan Tech allowing […]

Urethane Control Arm Bushings – Polyurethane Bushings

Urethane control arm bushings also know as “A-arm bushings” are installed in the steel rod that connects the hub to the vehicle. Made from a superior high-quality urethane prepolymer the urethane control arm bushings will last for many years and outperform rubber bushings 3:1. Plan Tech specializes in high volume urethane control arm bushings with prototype and lower volume parts also. Not only do just motor vehicles have control arm bushings as we have seen a huge demand in robot vehicles requiring special one-off custom size urethane control arm bushings. Most commonly the urethane will be bonded to a steel core for added strength and bolt on applications. Each steel core will be custom-made in-house at our machine shop before it is processed in our clean room before a bonding adhesive is applied directly to the core. Casting onto this surface allows us to mold urethane control arm bushings complete with no secondary process required and is ideal for high volume. Plan Tech also has many additives for changing the physical properties of the urethane for more lubricity or added tear resistance. Overall polyurethane is an ideal choice when searching for urethane control arm bushings due to its […]

FDA Approved Polyurethane Rods – Custom Urethane Rods

FDA approved polyurethane rods are custom cast from Plan Tech in many different OD sizes and lengths. Our most common specification for FDA approved polyurethane rods are for conveyor systems that use the FDA approved urethane rods to help guide product much like a bumper for sorting. Being able to tailor the physical properties of our urethane allows us to add a PolyMag additive in case any piece of the polyurethane rod were to break off it would be easily detected with excited X-ray equipment on the conveyor system. These high performance long lasting FDA approved polyurethane rods are available in any hardness from 20A to 95A and have all the great physical properties polyurethane has naturally. Plan Tech stocks FDA approved white pigment and can special order any FDA approved pigment from world-leading pigment suppliers. FDA approved polyurethane rods are ideal for packaging facilities looking for a lower cost approved rod that often times performs better than the OEM. Frequently Plan Tech will supply the FDA approved polyurethane rods in an oversized length for a secondary operation to the rod. Plan Tech specializes in secondaries on urethane parts and can also supply FDA approved polyurethane parts for […]

Recovering Urethane Rollers

Recovering urethane rollers is one of the main services Plan Tech provides for many industries requiring a covered roller. Urethane rollers typically consist of a steel core that will be stripped of any previous coating before being individually processed in our clean room for metal preparation. Taking this extra step produces a bond strength unlike any other urethane roller on the market. Our high strength bonding adhesive that is applied to any type of metal surface after being media blasted will ensure a quality bond that will never delaminate. Urethane is a great choice when weight out the options available for re-covering exciting or new rollers. Custom cast at Plan Tech in high or low volume recovered urethane rollers are available in any color and lengths under 4’ feet and less than 10’’ diameter. While most polyurethane bearings are covered in a 95A hardness for a smooth and quiet operation any hardness or color is available. Plan Tech will learn each new application and help suggest if any additives are necessary. By far our most common additive is called Armoglide which will add lubricity to the urethane material as it wears keeping the roller clean and product moving […]

Polyurethane Bearings – Polyurethane Covered Bearings

Polyurethane bearings also known as bearing with a tire offer greater physical properties than rubber and similar materials with the options for any bearings or OD profile. Custom cast at Plan Tech in high or low volume polyurethane bearings are available in any size or color. While most polyurethane bearings are covered in a 95A hardness for a smooth and quiet operation any hardness or color is available. Polyurethane has better abrasion and tear resistance than rubber while also being chemical resistance. Plan Tech can supply high-quality bearings from world leading bearing manufacturers in any size configuration for bolt on replacements or special applications. Each bearing will be individually processed in our clean room for metal preparation. Taking this extra step produces a bond strength unlike any other polyurethane bearings on the market. Our high strength bonding adhesive that is applied to each bearing after being media blasted will ensure a quality bond that will not delaminate. Plan Tech supplies millions of custom polyurethane bearings each year mainly for the distribution and shipping industry. Other industries include the car manufacturing, excess equipment, and custom woodworking. Whatever your application is Plan Tech will suggest the best material for […]

Urethane Bar Stock – Polyurethane Bar Stock

Urethane bar stock custom made to your requirements for low-cost replacement parts. Made from high-quality urethane material Plan Tech has several ways to produce tight tolerance urethane bar stock or low cast oversized bars. For 30 years we have been building our in-house tooling inventory to be able to produce urethane bar stock up to 10′ feet long, 1′ foot wide and up to 6” inches thick in any hardness or color. Depending on the application a variety of additives may be added to enhance physical properties of the urethane. FDA urethane requirements are also available in most durometers. Urethane bars have a great ability to absorb an impact and return to its original size even after years of repeated abuse. Urethane bars in die stamping applications are commonly referred to cutter bars, which can be easily replaced with urethane bar stock for any application. Custom details or profiles for urethane molded parts are available upon request as well. At Plan Tech we have an in-house water jet capable of cutting any profile or hole location for often times less than molded OEM original parts. We can also reverse engineer any urethane bar stock OEM from a sample part […]

How to Manufacture Custom Urethane Rollers

Manufacturing urethane rollers isn’t a basic process – it’s as much of a science as it is an art and takes years of experience. Fortunately, we have been able to master creating quality urethane rollers that have been used for various applications – from mass production to small scale. If you’ve ever wondered how to manufacture urethane rollers, or how it is that we produce our urethane rollers with such quality, it all centers around the following: How To Manufacture Custom Urethane Rollers 1. Advanced chemistry manipulation – Urethane rollers that are customized require a high level of chemistry knowledge. It sounds simple, but it’s a rather delicate balance of adding polyether’s and polyesters to modify polymers so they perform in a specific way. 2. Customized Made to Order Approach – When we manufacture our urethane rollers, you can think of it as ordering your favorite hamburger. You can pick and choose some of the “features” like lettuce, tomatoes, ketchup, etc. Also, choose how well done you’d like the meat. That’s how we approach the manufacturing process. It’s entirely dependent on your specification application requirements, exactly to your specification. How Are We Able to Customize Urethane Rollers? […]

Urethane Carriage Rollers – Polyurethane Carriage Rollers

Urethane carriage rollers are extremely common in many different profiles to match the riding or “carriage” surface track. Any hardness or color is available but 95A is recommended for most applications due to its nature to absorb an impact and return to its original size resulting in a smooth and quiet operation. Being 95A urethane material it will machine easily into almost any profile while holding extremely tight tolerances. Plan Tech processes high-quality Ether based prepolymers from world leading chemical companies. The polyurethane is suitable for any wet or humid environments. For high strength applications, a steel or stainless steel core added into the design. Each core for the urethane carriage rollers will be made at our state of the art machine shop. Plan Tech can supply 1 or thousands of urethane carriage rollers of just about any size. Each high strength core will be media blasted before a light coat of bonding adhesive is applied to the core in our. Each and every urethane carriage rollers are hand cast, sometimes if the profile allows molded rollers we will cast each part complete resulting in a low-cost replacement that often times exceeds OEM physical properties. Plan Tech’s team […]

Urethane Scraper Blades – Polyurethane Scraper Blades

Urethane Scraper Blades are large metal bars commonly coated with urethane to produce a soft blade to redirect product off a roller or to simply keep the roller clean while it process’s material. Other types of urethane scraper blades are on a much smaller scale and can be easily cut at Plan Techs state of the art machine shop equipped with water jet cutting capabilities. Any profile urethane scraper blades can be processed by either molding the large steel bar and finishing with light machining or be molding the scraper blade whole. The steel bar or “core” of the urethane scraper blades will enter our clean room where it will be greased and media blasted before a light coat of bonding adhesive is applied directly to the bar. Being able to process metal like this allows us to cast the urethane onto the core resulting in a urethane to metal bond unlike anything else. Similarly, ways of gluing the urethane to a bar may result in delamination and down time to the end user which can cost thousands of dollars. Any hardness or angle urethane scraper blades can be achieved at Plan Tech. OEM replacements or custom […]